A tech pack is a blueprint that helps designers and manufacturers communicate clearly. It includes technical specifications, design details, and everything needed to create the final garment with the required quality.

With cutting-edge fashion technology, you can even create factory-ready tech packs in under five minutes. Want to see it in action? Watch our demo video to see how it works!

Topics Discussed

ToggleWhat is a Tech Pack?

A tech pack is a set of documents created by you or your designer to explain the design to your manufacturing company so they can turn this information into a finished garment. It serves as a blueprint for the final garment and includes detailed flat sketches, materials to be used, trims, labels, measurement specs, size gradings, and colorways.

Without a clear and detailed tech pack, mistakes can happen in the finished product. A well-prepared tech pack eliminates guesswork, ensuring the final garment matches your vision perfectly.

For your clothing brand, working with professional manufacturers and factories requires more than just an idea. Like at Gears Sphere, we don’t take on any order unless the client provides a tech pack or even a mock-up.

Why Is A Tech Pack Important?

Here are some key reasons why tech packs are a must-have when creating a fashion product.

1. How a Tech Pack Saves Time and Money

A detailed tech pack helps prevent mistakes during sampling and bulk production by providing clear specifications. This ensures that your manufacturer follows the correct process from the start, reducing costly and unnecessary mistakes. Without a tech pack, your brand may face inconsistencies.

When every detail is documented, there is less back-and-forth, making the process faster and smoother. This also helps you bring the products to market without unexpected setbacks.

2. Gets You an Accurate Price Quotation

A precise tech pack makes it easier for the manufacturer to estimate costs by outlining the required fabric, printing, labor, quality, and production steps. Without clear details, pricing can be vague, leading to miscalculations that affect profitability.

A well-prepared tech pack ensures transparency, so the brand knows exactly what to expect. This allows for better budget control and helps prevent unexpected expenses.

3. Ensures the Best Fit for Your Product

A fit sample is crucial for checking whether your manufacturer has followed the right measurements. Once received, you can register the actual measurements on a fit sheet and compare them to the initial ones in a structured table.

This helps check if the dimensions fall within tolerance. By adding a custom column for adjustments, you ensure precise modifications, giving you room to refine the fit accordingly.

4. A Tech Pack Serves as a Production Manual

Product production is not a simple task that one person can manage alone. It requires collaboration between multiple teams, from design and material sourcing to sampling and final manufacturing. Each stage demands precision and efficient communication. A trusted manufacturing partner relies on a detailed tech pack or at least a mockup to ensure accuracy.

At Gears Sphere, we bring your designs to life. We are your one-stop solution for custom apparel production because we offer end-to-end manufacturing services from pattern development, sampling, bulk production, to printing, embroidery, and custom packaging (hang tags + next labels included ) that is totally for free, all while maintaining strict quality control.

They couldn’t bring your tech pack to life, We can!

If your brand doesn’t have a tech pack, no worries, we create one for your brand for free before production starts. Just click the WhatsApp icon in the bottom-left corner to chat with us. With everything under one roof, you focus on design and branding. We’ll handle the complexity of manufacturing and deliver quality apparel, exactly as agreed.

5. Speeds Up Production and Prevents Delays

A complete tech pack allows your manufacturer to speed up the sampling process. It helps bring products to market faster.

6. Ensures Consistent Quality Standards

During the production stage, it helps us to track materials, production details, and measurements to confirm that each article meets your specified requirements. Without this reference, errors may go unnoticed, leading to defects in the final product.

The manufacturer can compare the finished products with the tech pack right away to identify any issues and make necessary adjustments before delivering them to your home.

7. A Strong Foundation for Future Designs

A well-made tech pack is more than just a document for your products. It becomes a valuable asset for your future designs. Instead of starting from scratch, you can fine-tune minor details and reuse elements from past collections.

This not only saves time and resources but also ensures brand consistency, helping you maintain the quality that your target audience expects. You can also advertise your brand and products on social media for your future drops.

What does a Tech Pack Include?

Here’s a list of common details found in a typical garment tech pack. The specific information depends on the type of product.

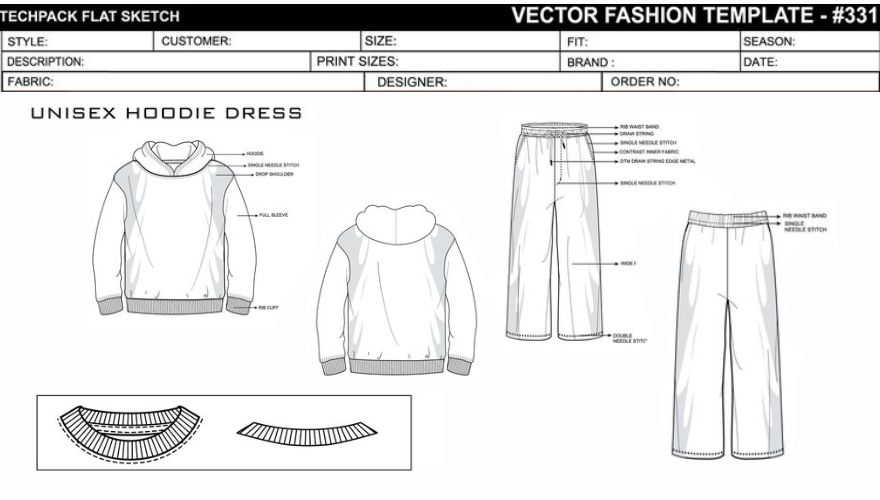

1. Fashion Flat Sketches

Technical sketches are essential in a tech pack because they illustrate a design in detail from different angles. These fashion flats show the front, back, side, and even inside views, helping your manufacturer and their pattern makers visualize the garment accurately.

A well-drawn sketch ensures the first sample looks as close as possible to your desired look. These sketches are usually done in black and white and are typically created in Adobe Illustrator for precision.

Include Multiple Views of your Garment.

A complete garment or accessory sketch is crucial before starting a tech pack. To make it easier for your manufacturer, sketches should include vantage points, side views, inside labels, and details. It’s important to write down even the obvious garment details.

Adding diagrams with labeled arrows pointing to collars, plackets, cuffs, fastenings, bar tacks, and artwork placement ensures every garment is manufactured exactly as intended.

Be as Detailed as Possible.

A thorough sketch helps your manufacturing company understand the design without confusion. Omitting parts can make it more difficult to explain. Clearly mark seams, darts, stitches, and button placements.

Use a solid line for the garment’s seam line and a dashed line to represent stitching. If any detail isn’t visible in the sketch, point it out separately in the tech pack to avoid misinterpretation.

Keep it Simple.

Adding details to sketches is necessary, but overcomplicating things can cause confusion. Avoid shading and use plain black and white sketches to clearly represent the design.

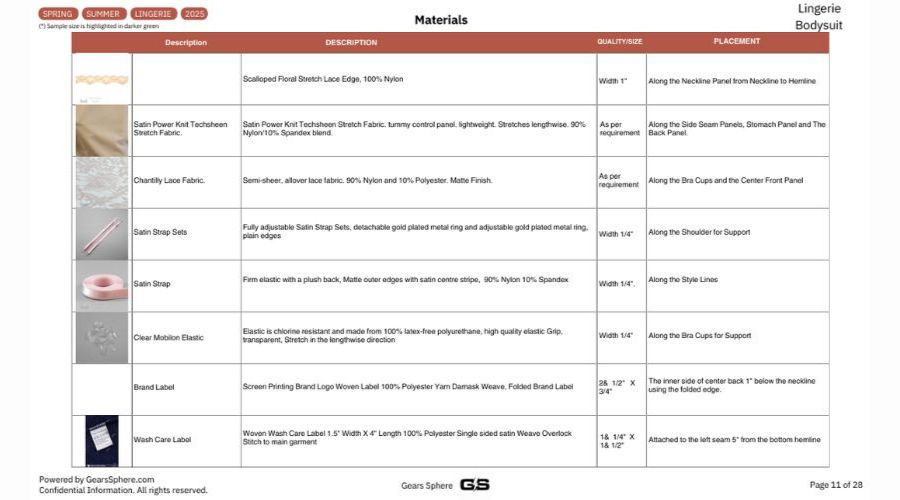

2. Bill of materials

A Bill of Materials (BOM) is a structured list of raw materials needed to produce a garment and prepare it for shipment. Any business that makes a physical product must carefully source materials to make it with the right quality.

Sourcing materials is an essential part of the production process, as the materials you choose can make a huge difference in the final product’s quality. A typical BOM table includes everything from main fabric, secondary fabric (lining), thread, trims, closures, labels, and packaging.

A technical designer creates the Bill of Materials in the apparel industry. He creates the Bill of Materials based on Computer-Aided Design (CAD) drawings to ensure accuracy. These are some advanced technical things, so don’t worry if you are a newbie in this industry because Gears Sphere has got you covered.

Why a Well-Defined BOM Matters.

A well-defined BOM table is important for these three main reasons.

- It determines the costing and pricing of the garment.

- It ensures that your factory doesn’t miss any essential components during production.

- It standardizes manufacturing to ensure quality and consistency in every batch.

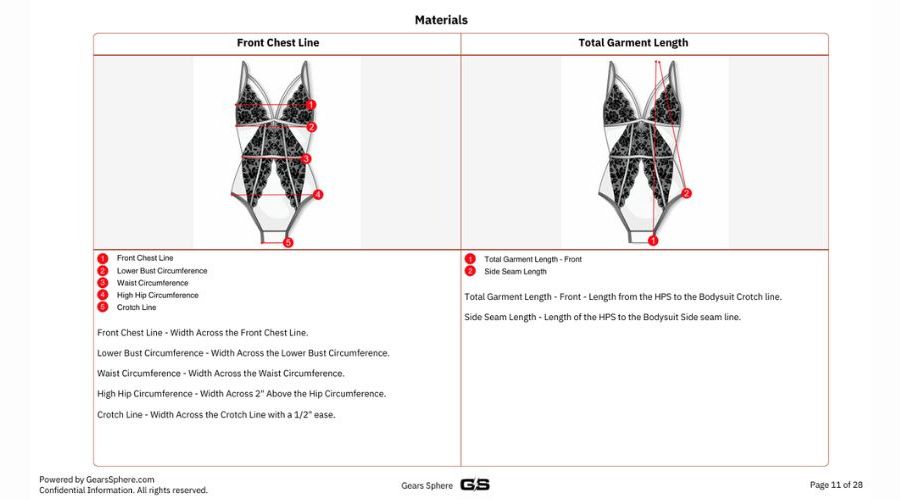

3. Garment Measurement Specs

The next step in creating a tech pack is adding a Garment Measurement Specs sheet, which includes measurements for every particular piece. A Measurement Specification Sheet lists the measurement specs for different components of a garment.

Typically used for every design, this sheet covers essential details like body length, chest, waist, hips, armhole, shoulder drop, neck opening, and more.

For a complex garment, additional points of measurement must be included, such as collar length, width, cuff length, and pocket measurements. A garment measurement sheet is one of the most critical documents needed to produce a well-fitting piece of clothing.

Mistakes in the spec sheet may result in a loss of time and money, leading to garments that don’t fit properly. These sheets are created based on standard sizing charts or adjusted according to custom body measurements to ensure the best fit.

4. Garment Cost Sheet

A Garment Cost Sheet helps calculate the total cost of a piece of garment by breaking down key expenses. A cost sheet typically includes the material cost, labor cost, and cost of processing to ensure accurate pricing.

Since each type of product has different specifications, a detailed costing table is crucial. Missing essential elements or details in the cost sheet can lead to miscalculations, especially for complex garments with multiple components.

To calculate the final cost of a garment, brands must specify every component used in its manufacture. This includes main fabric, lining, interfacing, trims, buttons, zippers, embellishments, appliqués, and more.

A well-structured costing table should also include other essential details, with quantities listed in a separate column to facilitate easy visualization and calculation. Even small parts commonly found in products, like hang tags, woven labels, neck labels, sewing thread, and packaging materials, should be added to the costing table to ensure no product elements are overlooked during creation and pricing.

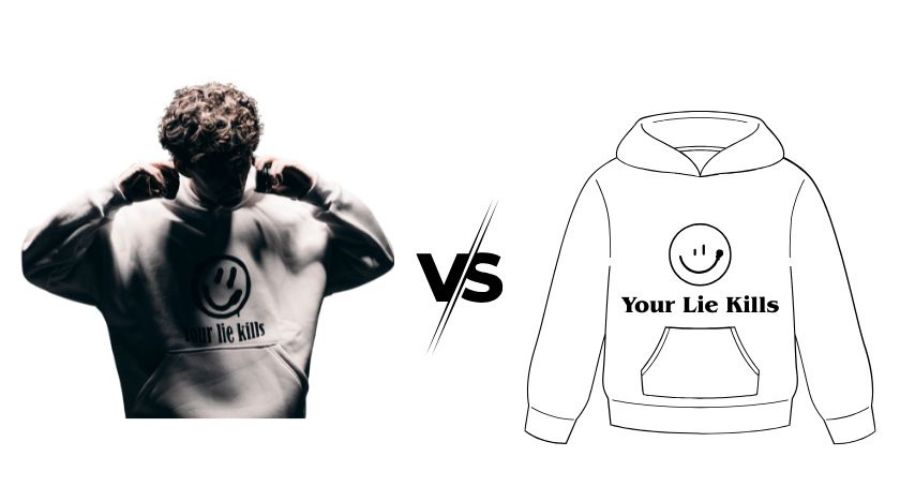

Tech Pack Examples and Templates

Now that you’ve learned the things to add in a techpack while creating it, here are some examples to help you understand the details better. We respect the privacy of our customers, so we can’t share their actual tech packs.

However, here are some sample tech pack templates that showcase the level of detail required for professional manufacturing. These templates highlight key elements like sketches, materials, and specifications needed to bring a design to life. Again, if you are a newbie, don’t get puzzled by all these technicalities; we can produce your products and ship them based on a simple mockup alone.

Menswear Jacket

Click below to view Men’s Jacket Tech Pack Example

Lingerie Bodysuit

Click below to view Lingerie’s Tech Pack Example

How to Create a Tech Pack

For years, Microsoft Excel has been the de facto tool to create tech packs in the fashion industry. It’s versatile and jam-packed with features, making it a familiar choice for teams used to working with spreadsheets.

But here’s the crux of the problem—traditional tech packs built in Excel lack efficiency. Design teams using spreadsheets cannot collaborate in real-time, leading to delays when versions are shared back and forth through endless emails.

On top of that, spreadsheets are static, with product info spread across different files and folders. Creating seasonal tech packs this way is slow and inefficient, as the product information remains disconnected and fragmented.

Luckily, modern solutions like Canva uses cloud-based software to streamline product development and avoid production delays. Unlike Excel, they offer a visual approach, allowing teams to view the entire product development process at a glance without constantly switching tabs, double-checking formulas, or manually editing different sections.

With a single page layout, teams can access sketches, a bill of materials, point of measurements, and costing tables, all in one place. The best thing is that you can simply reuse design specs for future collections.

Plus, teams can collaborate efficiently by adding comments, tagging each other, and communicating in real-time, ultimately speeding up the product development process.

Can You Build a Perfect Tech Pack in 5 Minutes?

Key Challenges Without A Clothing Tech Pack

As a clothing manufacturer, I know firsthand that a tech pack is one of the most important considerations in product development. Even though we provide each and every update of manufacturing through video calls to our clients, a tech pack or even a mockup with reference images still plays a critical role.

It outlines almost every aspect of the product specification, from fabric yardage, trims, and accents to size details. Without it, there’s a risk of overlooking key details, leading to decreased quality control and potential financial losses due to corrections and reworks.

Not having a tech pack could mean receiving too little or too much material, the wrong colors, unexpected texture variation, or an incorrect cut size. These scenarios can disrupt production. In short, it’s for your own benefit. It is just like a two-step verification for your brand.

Advantages of Using Digital Tech Packs in Fashion

Digital tech packs are revolutionizing how brands and manufacturers manage their projects with built-in, cloud-based software. Teams can enjoy a seamless experience, ensuring accuracy, efficiency, and real-time collaboration.

- Quick to produce

- User-friendly interface

- Seamless sharing

- Synchronized workflow

- Unified data hub